With the shell now completely painted in 2K epoxy primer, the process of sand/clean/rust converter/clean/prep was repeated for both sides of the bonnet, doors, bootlid and bonnet slam panel.

I sorted through all my parts storage boxes to find as many factory and custom made parts as I could for the Mini, then spent a substantial amount of time sand blasting and painting (2K epoxy primer) each and every part. Some of these will be painted in the final body colour however most will eventually be painted black.

Underbody fuel line / battery cable covers & door card trim tops :

Misc factory & (mostly) custom brackets/parts :

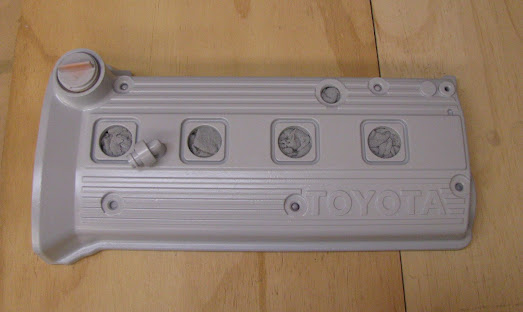

The engine cam cover had previously been painted with 1K enamel however it was less durable than I'd hoped so it was re-blasted and rinsed/cleaned thoroughly to remove all blasting grit. I stuffed some rags in the openings so the spark plug tube seals and baffle did not get covered in overspray, and 3D printed a simple cap to block the oil fill opening. It will be sanded and painted in the body colour at a later date.

The master clutch and brake cylinders (purchased new 11 years old) showed initial signs of surface rust so before blasting I painted a few sample pieces and tested the effect of brake fluid (left for 1 hour) on a couple of paint types - 2K, acrylic enamel, epoxy enamel - to confirm which one was the most resistant to brake fluid affecting the paint. As expected, the brake stripped the enamels but the 2K paint was only slightly discoloured, so the cylinders will later be painted with a silver 2K top coat.

The (sandblasted) front subframe was also painted with a coat of KBS Coatings RustSeal (rust preventive coating/sealer), and 2 coats of satin black enamel - RustSeal is not UV stable and requires a topcoat.

Comments

Post a Comment