Before any primer was applied to the Mini, the bodywork had to have any last dents, body gaps and panel alignments fixed.

The items that were attended to were :

Minor dents beaten out of floorpan and boot floor

Panel beating the deseamed areas in the A-Pillars & front guards

Oil canning in parts of the bonnet, fixed with heat shrinking in localised areas (the dark circular spots).

Fix multiple areas of rust damage in door outer door skins, where it folds over the door edges

Before :

I fitted the bonnet & started aligning it with some panel gap tools.

I made some brackets to hold the front end in place with a ratchet strap whilst welding the apron back together.

The remainder of the bonnet gap was fixed with some panel beating on the bonnet to correct the extra 1-2mm.

I also made a new route for the wiring into the doors since my previous idea of routing the wiring over the door check strap resulted in the wires being bent too tight once the door was closed.

The old wiring route design :

There were a few iterations of ideas to mount the cable/conduit however I ended up with a design with a 90degree bend for the wiring contained within a length of conduit, where it clears the door rubber seal when the door is opened and closed.

This design is much better to mitigate long-term wire damage as the wires move far less in this layout with no tight bends/kinks. You can see in this pic how tightly the wires would have bent if they were attached to the check strap. Once everything is painted black it will be well hidden with the black carpet.

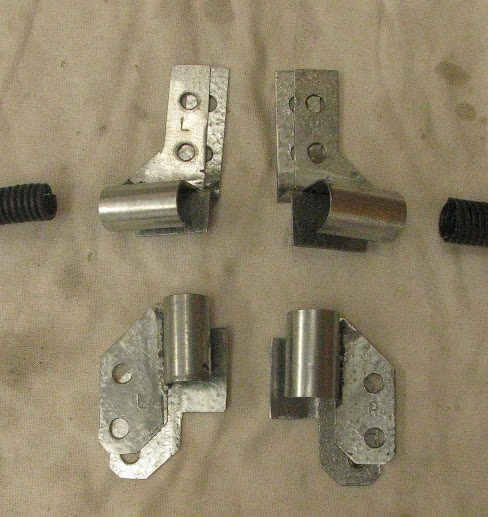

The two-piece brackets are bolted behind the check strap mounts and clamp onto the conduit.

The Mini now looks like a semi-completed car for the first time in years.

Comments

Post a Comment