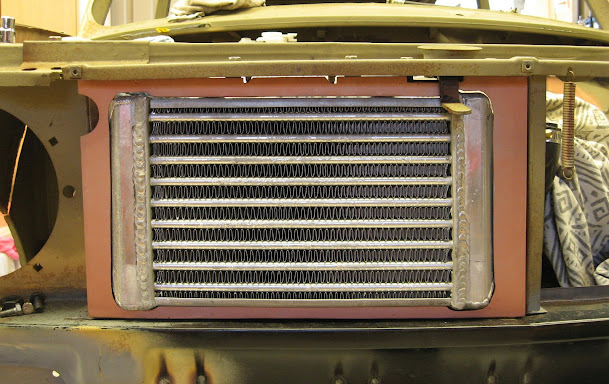

Continuing on items in the engine bay...

The semi circle on the left hand side of the shroud is to allow air to feed the alternator cooling duct

I also had to make a small cutout to clear the grille mounting tab.

While I was working on the intercooler shroud I found there was large crack in the bonnet latch which broke with only a small amount force applied to it.

To repair this I simply cut a new section of steel for the latch handle, bent and TIG welded it together.

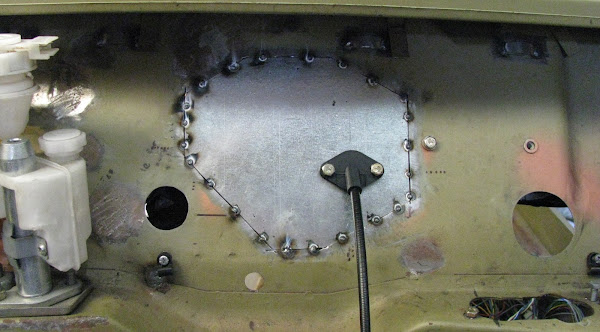

I needed a vacuum/boost line in the cabin for the boost gauge, and I could have simply passed some vacuum line through a grommet in the firewall but I wanted something neater. I machined a fitting on the lathe and filed some flats on the centre to fit a 10mm spanner.

The fitting bolts through a rivnut in the firewall and the vacuum line in the cabin will simply push on the other end of the fitting.

I didn't have a bonnet stay/prop rod when I bought the Mini for this project. The factory Mini design has the stay rod very loosely secured through a bare bonnet bracket so I sourced a plastic bonnet stay clip and fitted it to the Mini bonnet by enlarging the factory bonnet bracket hole and pressing in the plastic clip which will stop the rod from rattling.

I bent a new stay rod using a 1/4" steel rod to copy one that I had photos of, and it seemed to hold the bonnet securely.

Comments

Post a Comment